2025-01-15 De-molding in Powder Metallurgy Injection Molding (MIM): A Unique ProcessPowder Metallurgy Injection Molding (MIM) is a technology that combines metal powders with binders and uses injection molding to create complex parts. Many people wonder: "Do MIM products require de-molding?" The answer is yes,

Read More

2025-01-13 As the New Year approaches, MIMO held its grand annual meeting at the end of 2024, themed "Together We Create and Reach New Heights." This meeting was not only a summary of the achievements from the past year but also a look ahead to the promising future. All employees gathered together to share in

Read More

2025-01-08 In the field of powder metallurgy, the quality of raw materials directly determines the performance and stability of the products. As a company with extensive experience in Metal Injection Molding (MIM), Mimo has always adhered to high standards in selecting steel powders to ensure product quality f

Read More

2025-01-01 In the field of Metal Injection Molding (MIM), minimum wall thickness is a key indicator frequently mentioned in design and manufacturing processes. It directly affects the feasibility of part production, performance, and manufacturing costs. For many industries that pursue precision and lightweight

Read More

2024-12-30 Iron-based powder metallurgy (PM) components are known for their excellent mechanical properties and cost-effectiveness, making them a popular choice in industries requiring strong, durable materials. The pressure resistance of such components largely depends on factors like material composition, ma

Read More

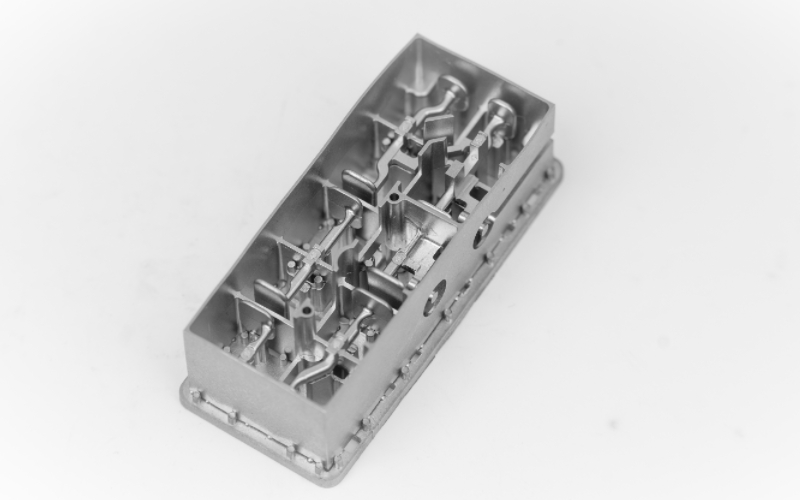

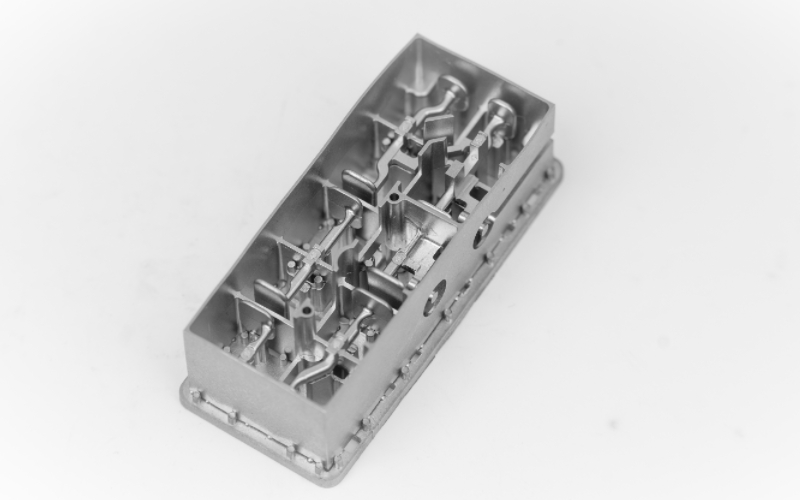

2024-12-19 1. High Precision and DensityMIMO Metal employs advanced powder metallurgy techniques to ensure precise dimensions and uniform density for keyways. With strict process control and quality inspection, our keyway products provide perfect compatibility during assembly, guaranteeing stability and durabi

Read More