2026-02-09 Jiangsu Mimo Metal Co., Ltd. (hereinafter referred to as “Mimo Metal”) has made a strategic layout in high-end manufacturing and invested 280 million yuan in the construction of a new factory. At present, the Phase I factory has been completed and put into trial operation after the installation and

Read More

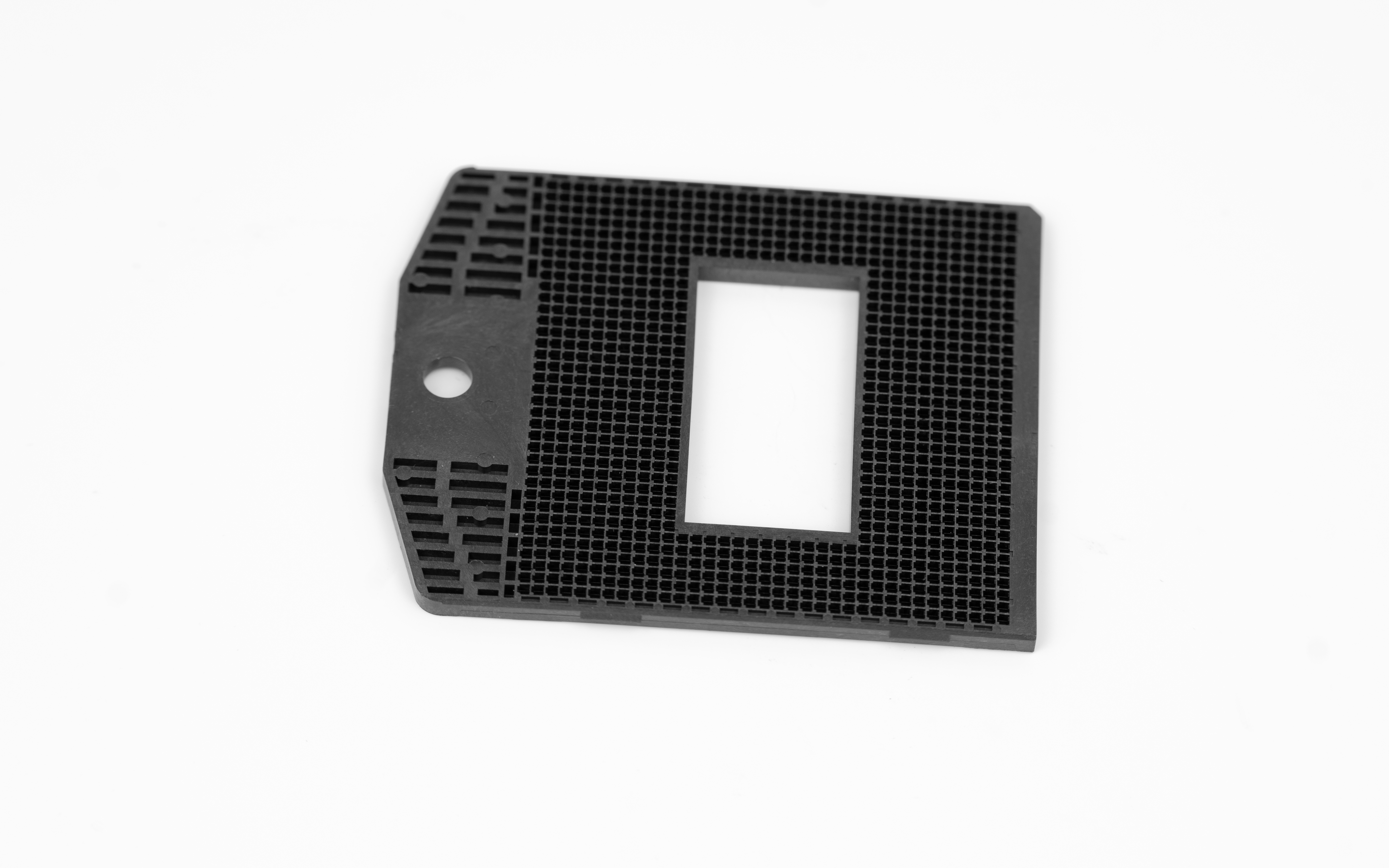

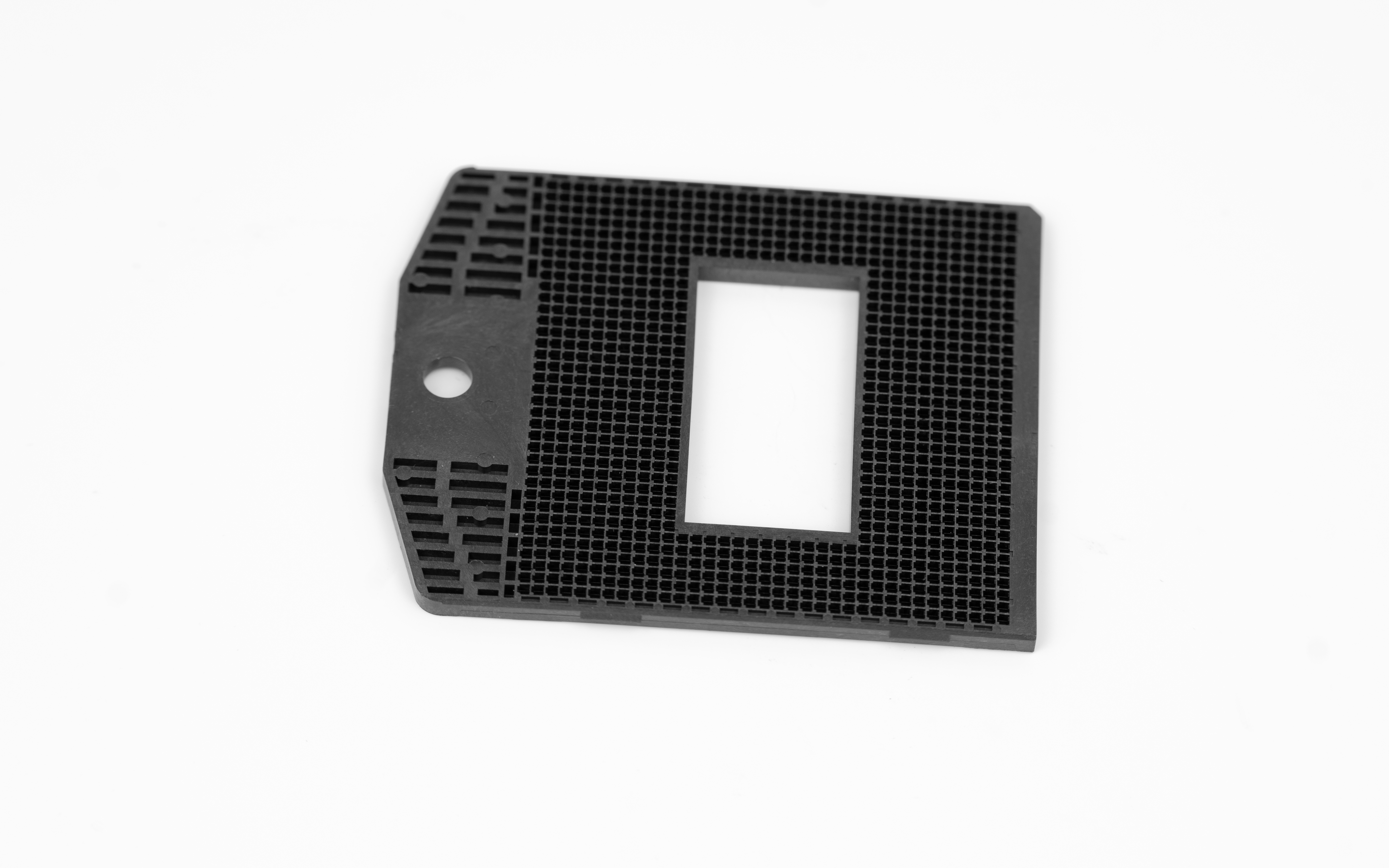

2026-02-26 The consumer electronics industry is rapidly evolving toward slimmer, miniaturized, and high-precision designs. Products such as smartphones, smart wearables, and earphones impose increasingly stringent requirements on precision metal components. Traditional manufacturing processes struggle to balan

Read More

2026-02-26 In the field of precision manufacturing, "high precision, complex structures, and large-scale mass production" have long been the core goals pursued by the industry. Traditional processes such as machining and precision casting have long been constrained by bottlenecks: precision and efficiency cann

Read More

2025-12-24 Amid the wave of manufacturing transformation toward "high efficiency, high precision, and low cost", Metal Injection Molding (MIM) technology has emerged as a key solution to address the challenges of traditional metal forming, thanks to its unique process advantages. Particularly under the dual co

Read More

2025-12-11 In the field of high-end manufacturing, the mass production of complex-shaped metal parts has long been a persistent industry challenge. From precision components in aerospace to micro-parts in medical devices, traditional machining processes either struggle with difficult forming or are constrained

Read More

2025-11-21 In the precision manufacturing industry, "high efficiency" and "low cost" are often difficult to achieve simultaneously, but metal injection molding (MIM) technology breaks this dilemma. As an innovative technology integrating powder metallurgy and injection molding processes, it achieves a dual bre

Read More