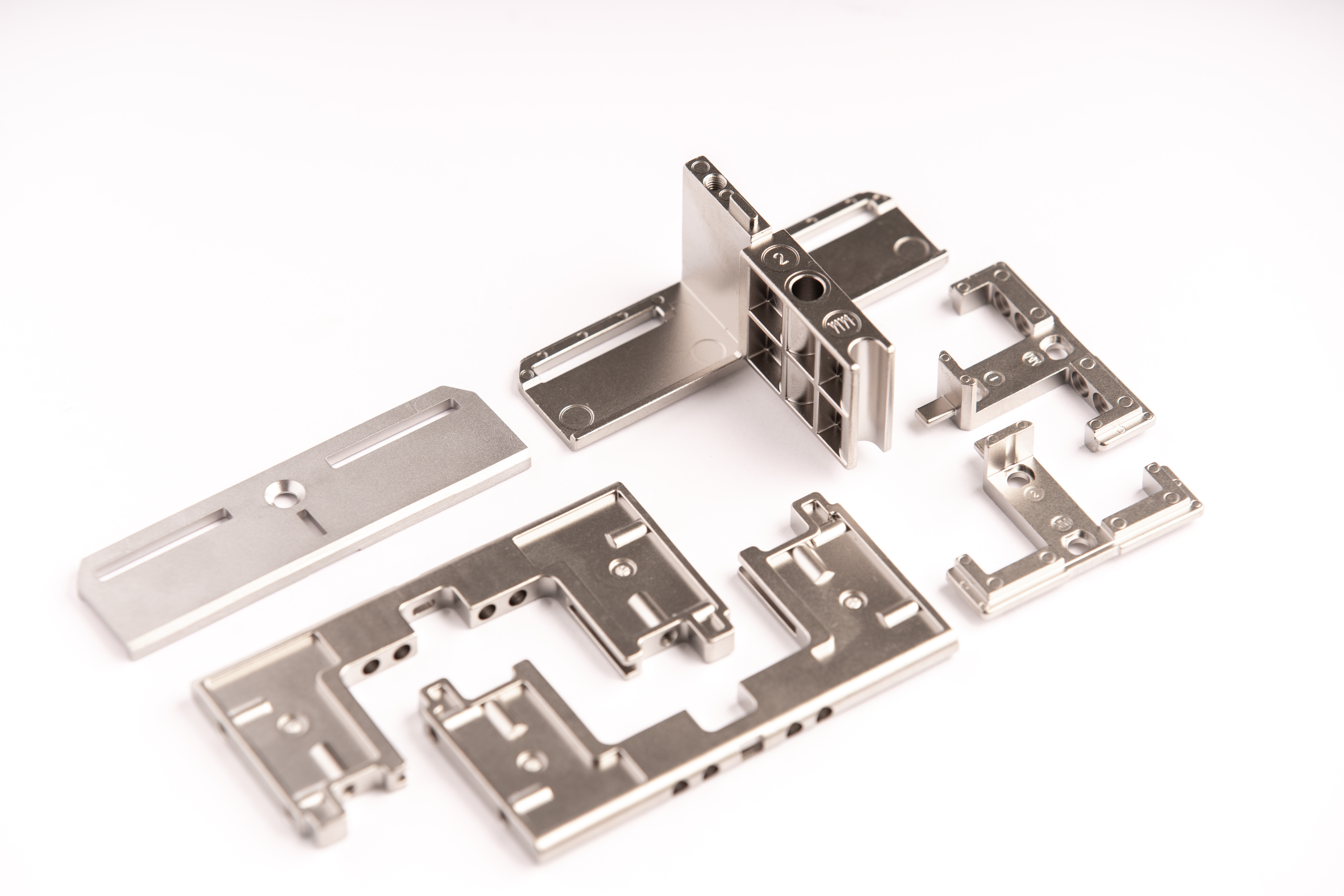

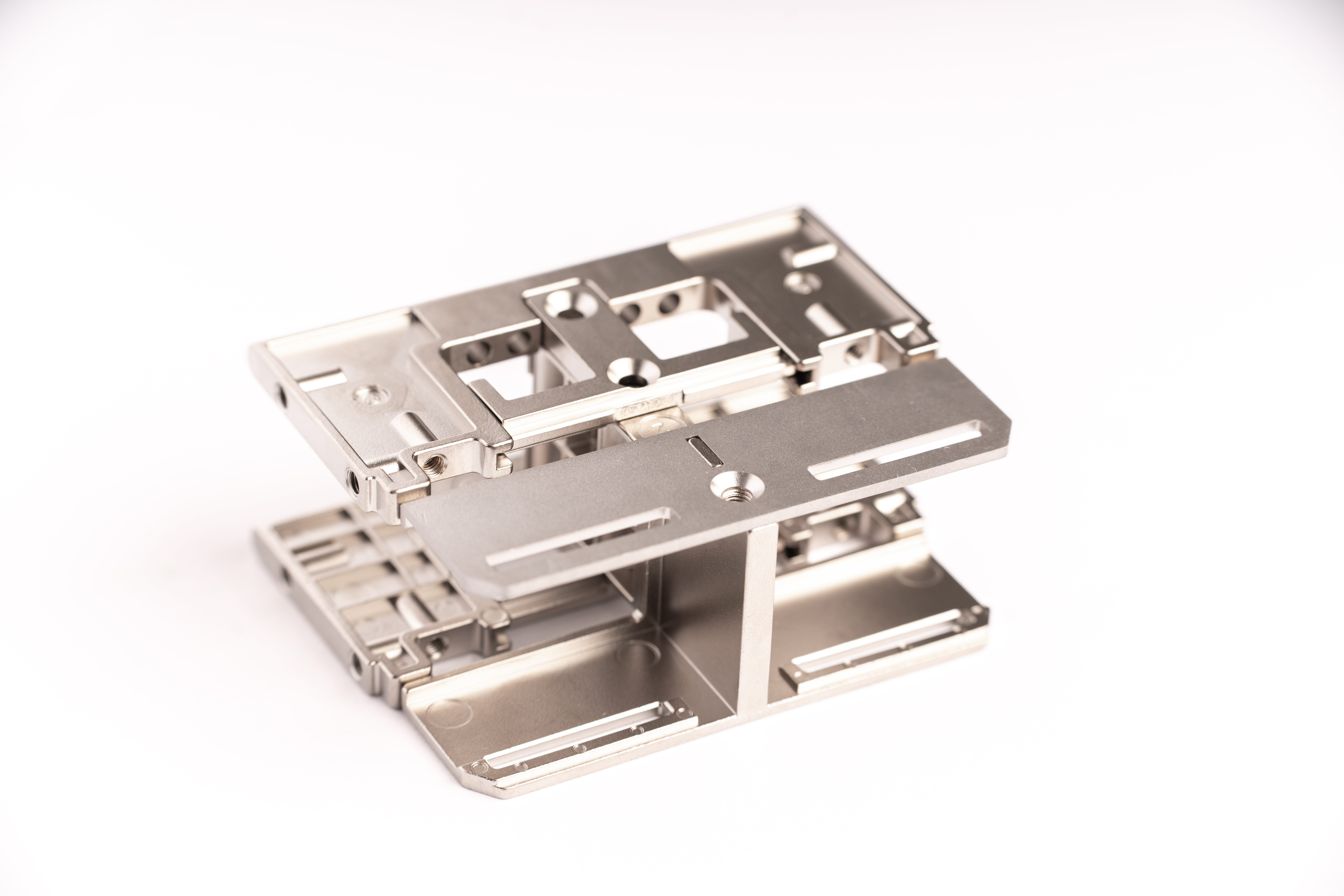

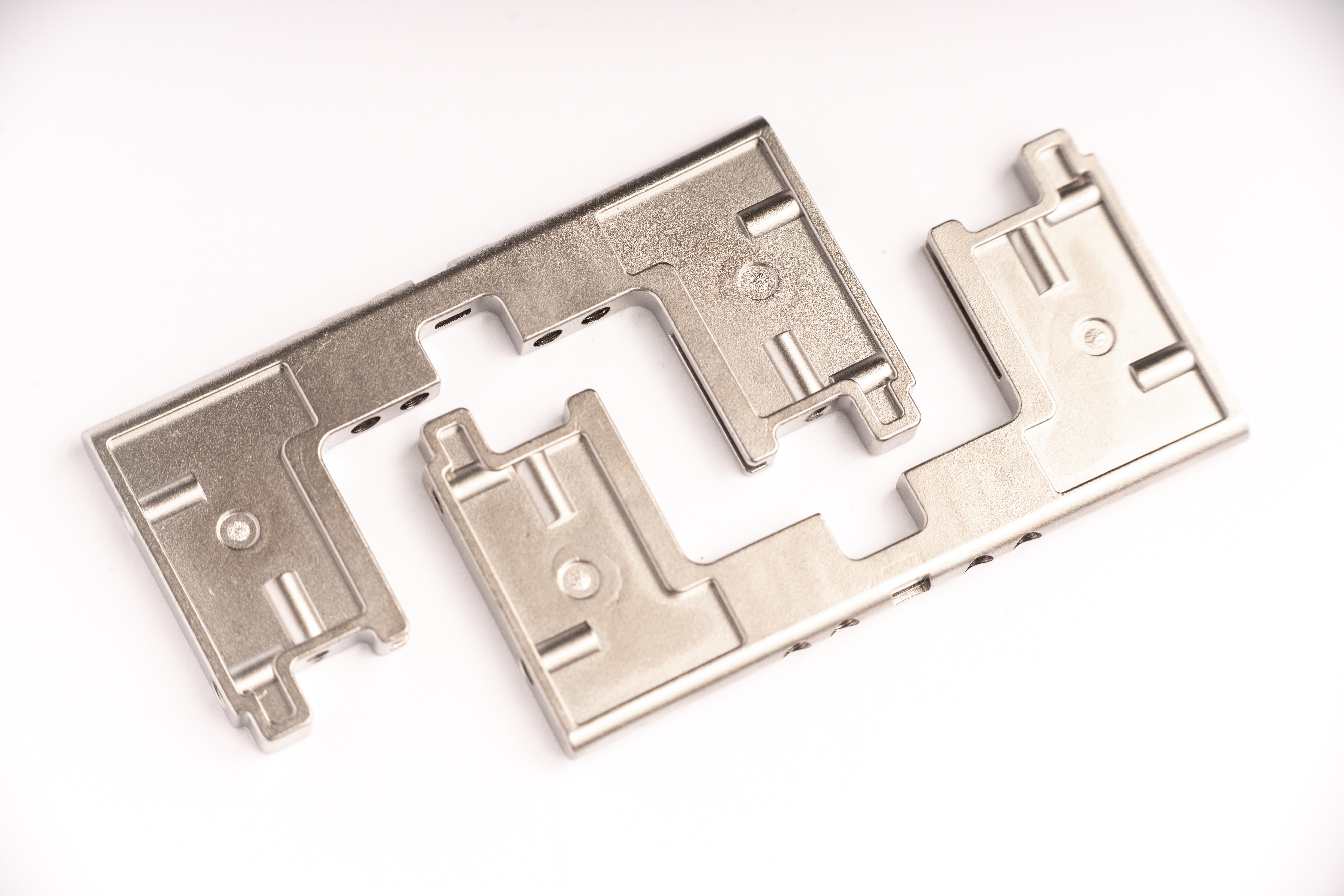

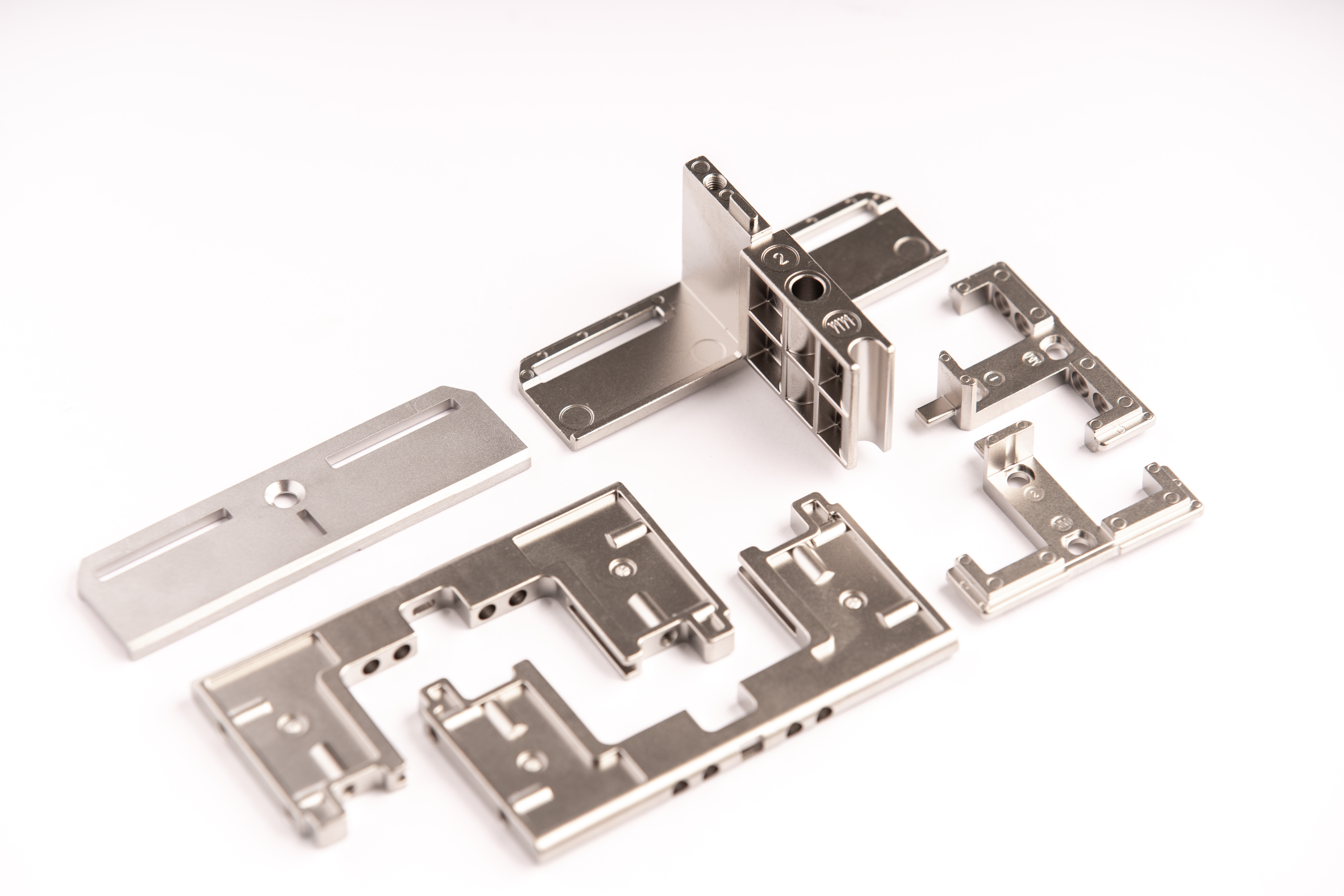

2025-10-29 To achieve high-precision metal parts production through Metal Injection Molding (MIM), the following key aspects can be addressed:Raw Material Selection and Preparation: Select metal powders with fine and uniform particle sizes, typically ranging from 2 to 25 micrometers. For instance, the particle

Read More

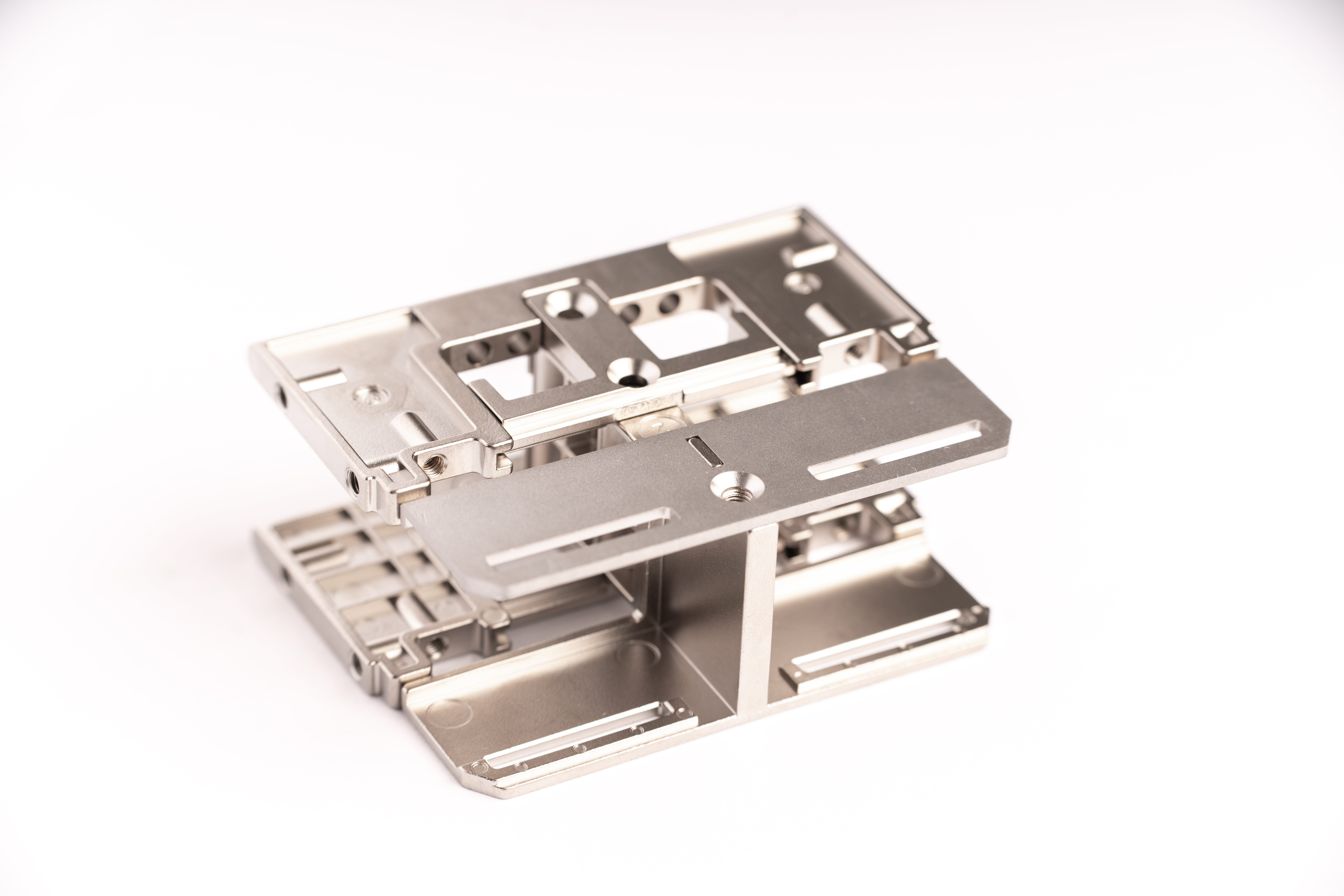

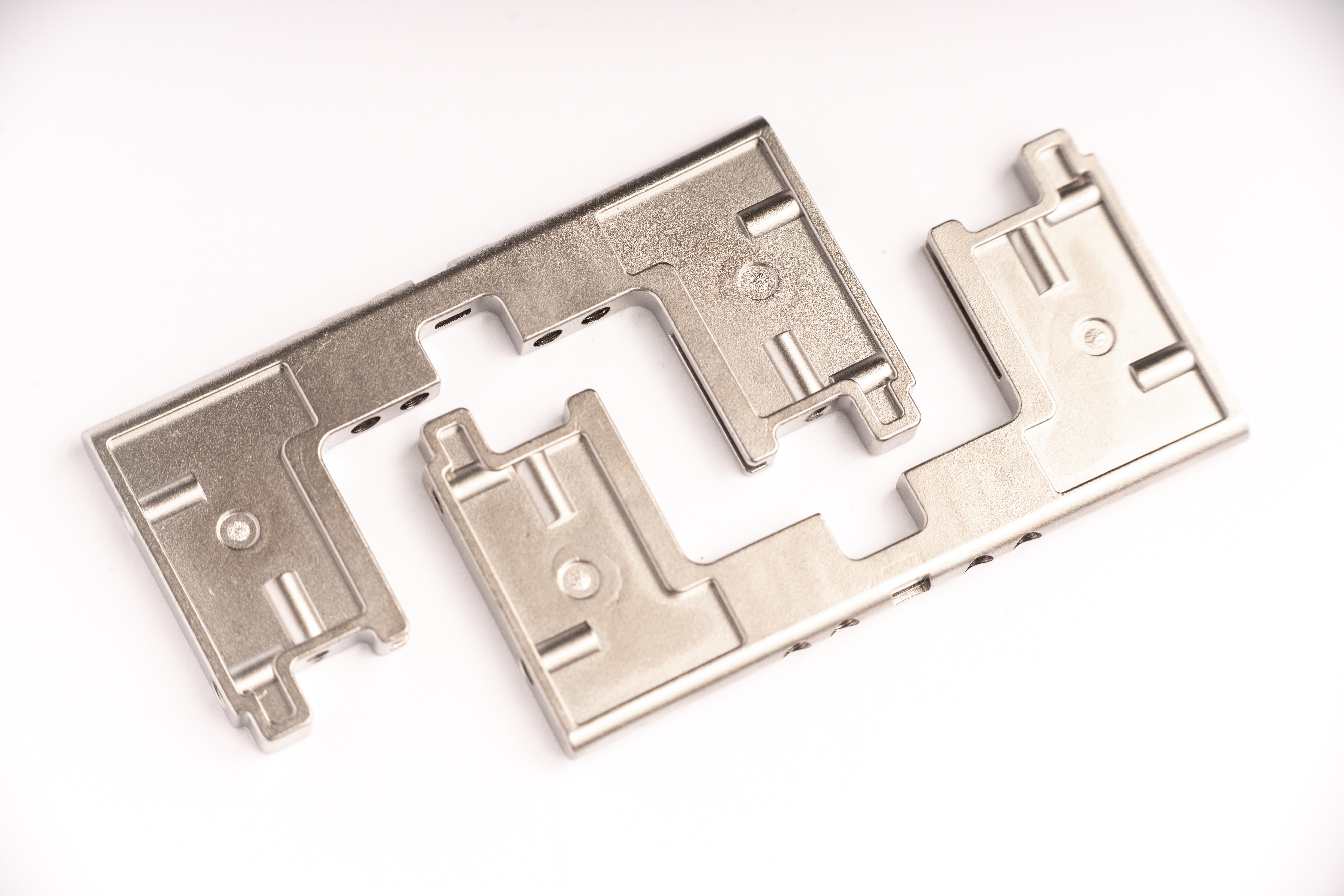

2025-10-28 Metal Injection Molding (MIM), as an advanced technology that integrates plastic injection molding and powder metallurgy, has become a key process in high-end manufacturing due to its advantages of "complex molding + mass production." The process involves four core stages, each relying on breakthrou

Read More

2025-10-28 In the field of precision manufacturing, the processing of complex components (such as parts with microholes, thin walls, and non-standard structures) has always been a major industry challenge. Metal injection molding (MIM), with its unique process characteristics, has become a key technology for o

Read More

2025-09-23 The powder metallurgy stainless steel process primarily involves the following steps:1. Powder Preparation: Typically, water atomization is used to rapidly cool and solidify molten stainless steel through a high-pressure air/water stream into a fine, spherical powder.2. Powder Mixing: The stainless

Read More

2025-09-15 In the development of modern manufacturing, breakthroughs in materials technology have always been a key driver of industrial upgrading. As a unique material preparation and forming technology, powder metallurgy, with its significant advantages in material utilization, performance control, and compl

Read More

2025-07-17 IntroductionMetal Injection Molding (MIM) stands out as a highly efficient and precise manufacturing process, demonstrating immense potential in the production of complex metal parts. However, in the pursuit of precision and functionality, the surface treatment of these MIM parts is equally crucial.

Read More