Views: 10 Author: Site Editor Publish Time: 2024-12-17 Origin: Site

Powder Metallurgy Injection Molding (MIM) combines plastic injection molding with powder metallurgy technology, offering an efficient method for manufacturing complex metal parts. In the MIM process, annealing plays a critical role in determining the mechanical properties, microstructure, and dimensional stability of the parts. Annealing involves heating metal parts to a specific temperature, holding them at that temperature, and then cooling them slowly. For MIM parts, the primary goals of annealing are to relieve internal stress, optimize the microstructure, enhance ductility, and ensure dimensional stability. Parts treated through annealing demonstrate significant improvements in mechanical performance and are better suited for subsequent processing.

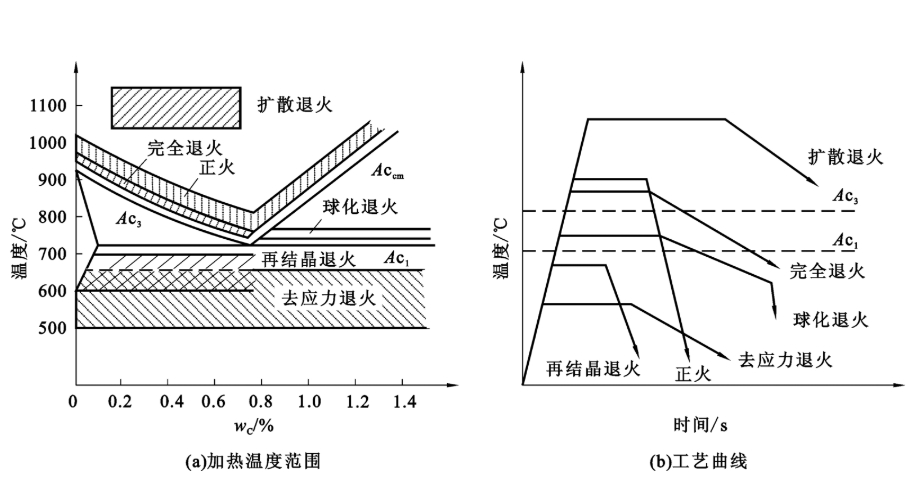

The annealing process typically comprises three stages: heating, holding, and cooling. During the heating phase, parts are gradually brought to a predetermined annealing temperature based on their material properties—for example, stainless steel typically requires 800–950°C, while iron-based alloys range between 600–800°C. At the target temperature, the parts are held for a sufficient time to ensure uniform temperature distribution, improving the microstructure and relieving internal stresses. Finally, the parts are cooled using appropriate methods. Furnace cooling is ideal for parts requiring complete stress relief, while air cooling is more efficient and suitable for applications with less stringent dimensional requirements. These controlled steps comprehensively enhance the parts' performance.

The application of annealing significantly improves the overall properties of MIM parts. It enhances fatigue resistance, wear resistance, and corrosion resistance while reducing energy consumption and carbon emissions. Compared to traditional forging annealing, the MIM annealing process is more energy-efficient and environmentally friendly, aligning with modern green manufacturing principles. Its efficiency and stability integrate seamlessly with the continuous production flow of MIM processes, ensuring product consistency and making it suitable for large-scale production.

Annealed MIM parts have found widespread applications in aerospace, medical devices, automotive components, and electronics. Notable examples include high-strength gears, wear-resistant valve bodies, and precision housings. By continuously optimizing annealing parameters, MIM technology is expanding its application scope and delivering high-performance solutions for various industries.