2024-06-07 selecting powder alloys suitable for MIM processes requires careful consideration of flowability, sintering performance, chemical composition, thermal properties, mechanical performance, and corrosion resistance.

Read More

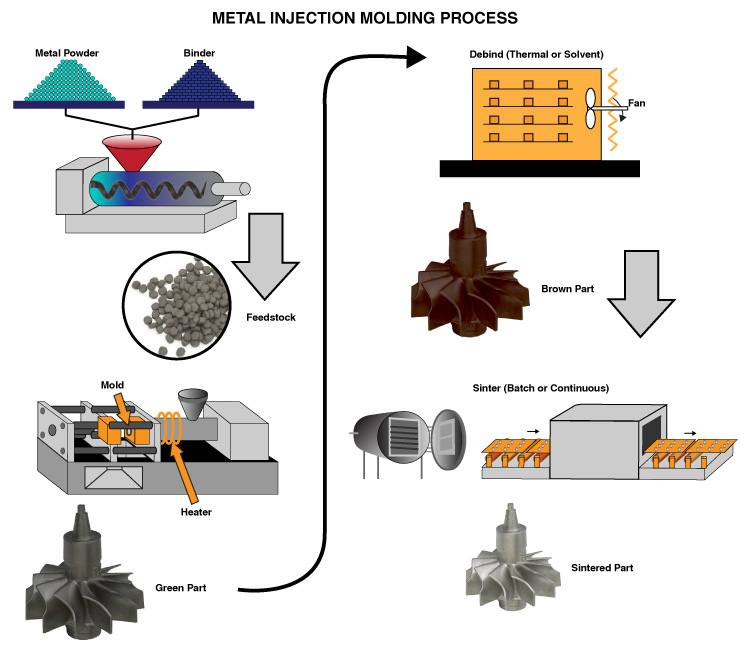

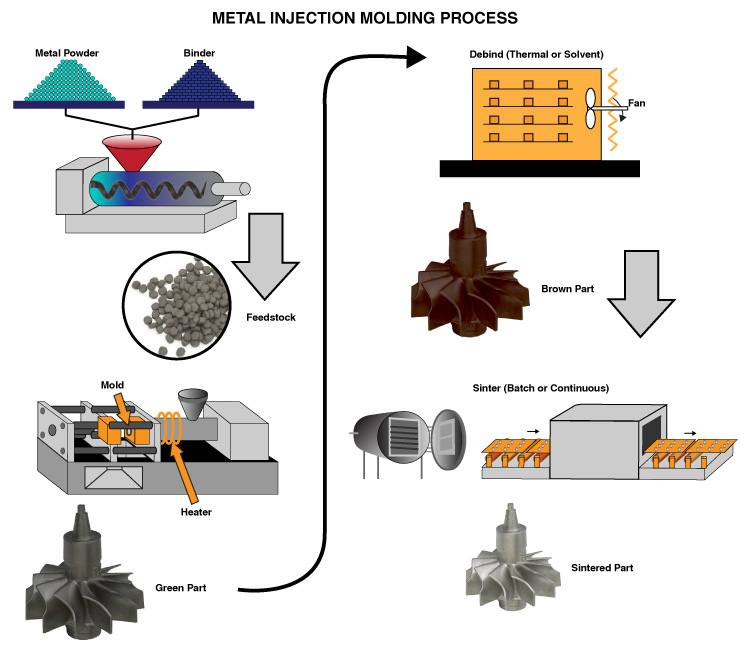

2024-06-07 Metal Injection Molding (MIM) is a manufacturing process that combines the flexibility of plastic injection molding with the strength and integrity of powdered metallurgy. This method is particularly advantageous for producing complex and high-performance automotive components. However, achieving hi

Read More

2024-06-06 IntroductionMetal Injection Molding (MIM) is a versatile manufacturing process that combines the design flexibility of plastic injection molding with the material strength of powder metallurgy. MIM is capable of producing complex shapes and high-precision components, including threaded parts. This r

Read More

2024-06-06 Metal Injection Molding (MIM) is an advanced manufacturing process that combines metal powders with a binder material to form complex and high-precision metal parts. Due to the high demands on material performance and product quality, the selection and characteristics of metal powders used in MIM ar

Read More

2023-08-22 Machined surface roughness is too large and too small will not wear. CNC machining surface roughness is too large, the actual pressure of the contact surface increases, rough convex peaks bite each other, crack, cut off, so wear intensifies;On the other hand, the machining surface roughness is too s

Read More

2023-08-21 BENEFITS OF METAL INJECTION MOLDING (MIM)✓ 96-98% of Theoretical Density✓ Excellent Mechanical Properties✓ Avoids Costly Secondary Operations✓ Excellent Surface Finishes✓ Capable of Extreme 3-D Geometries✓ Holds Tight Tolerances✓ Extremely Thin Wall Section Capabilities

Read More