2024-08-16 Powder Metallurgy Injection Molding (MIM) and Fine Blanking are two common processes for manufacturing complex metal parts. Each has its advantages, and their cost structures differ. Below is a comparison from multiple aspects:1. Material Utilization and WastePowder Metallurgy Injection Molding (MIM

Read More

2024-08-09 Powder Metallurgy Injection Molding (MIM) technology is known for its excellent mechanical properties, such as high strength and hardness, making it an important process for manufacturing precision components. However, the impact resistance of components is not fixed; it is influenced by several fac

Read More

2024-08-08 In August, MiMo Metals hosted a heartwarming birthday celebration for its employees. The event brought together colleagues from various departments and positions within the company, including vibrant new faces born in 2004 and dedicated veterans who have served MiMo for fifteen years. Attendees came

Read More

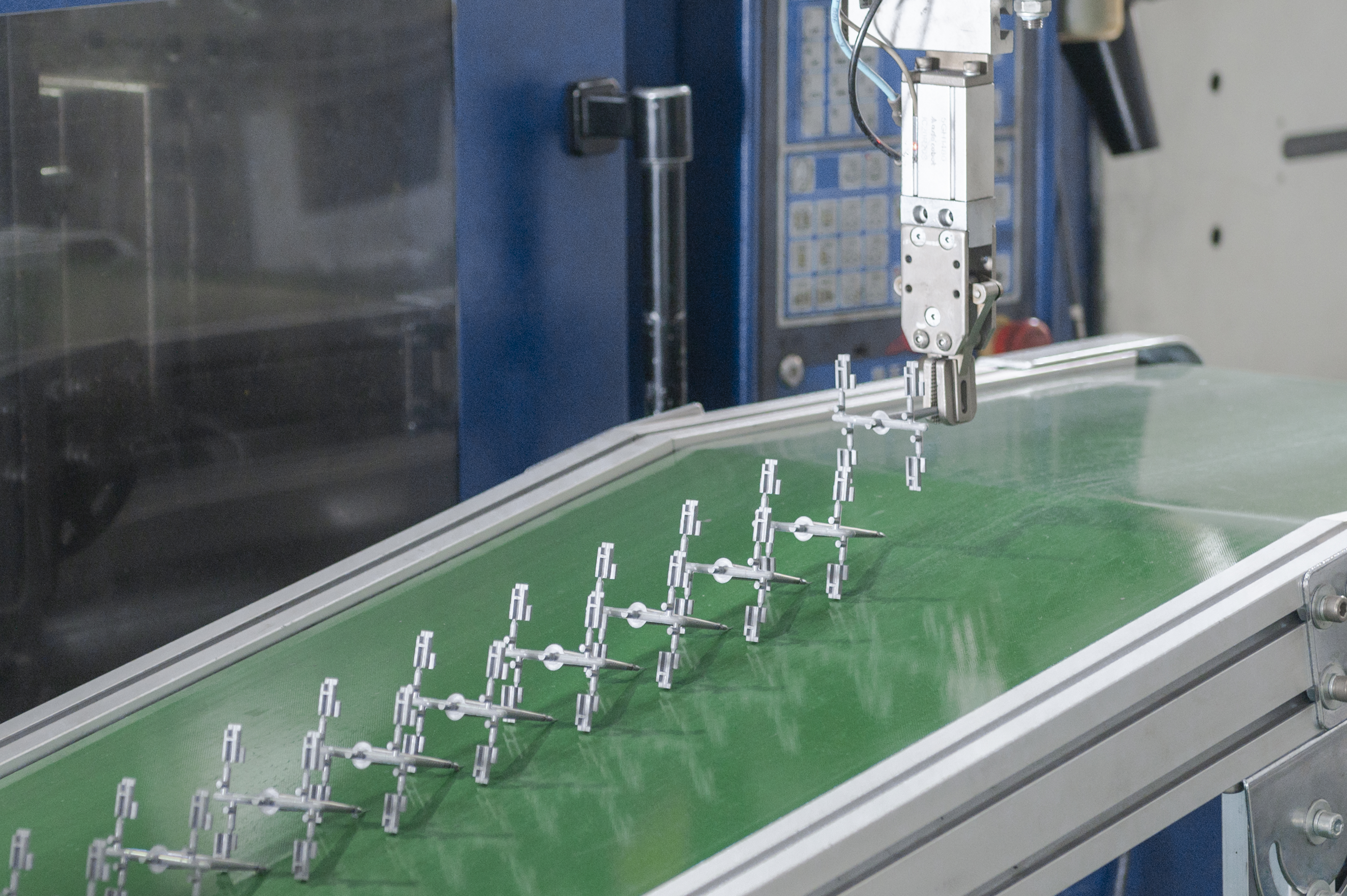

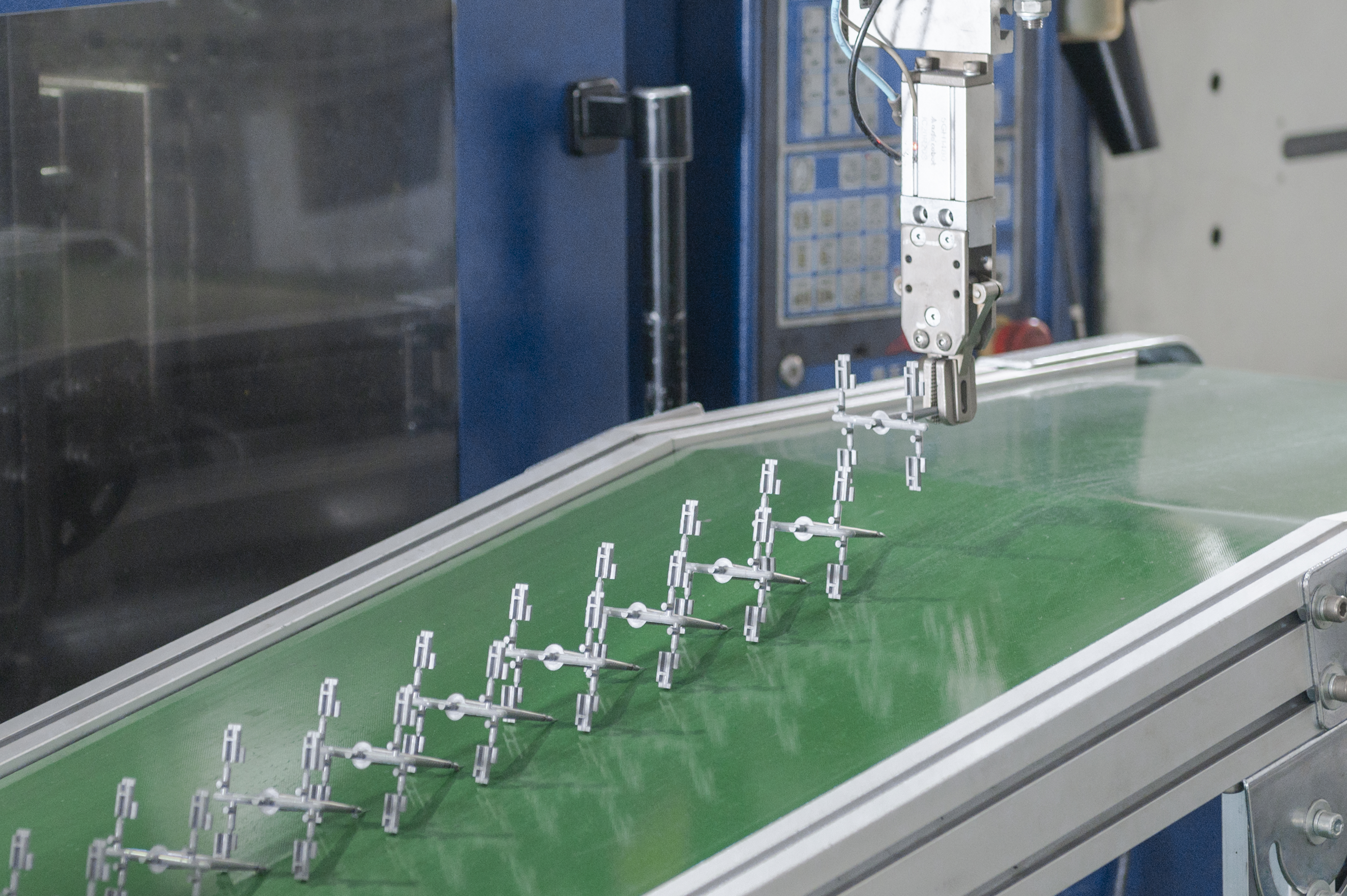

2024-08-02 The manufacturing process of dense thin sheets using Metal Injection Molding (MIM) technology presents numerous technical challenges. Through continuous research and technological innovation, MIMO has successfully overcome these challenges and delivered high-quality products that satisfy its custome

Read More

2024-07-25 The elastic modulus of powder metallurgy materials refers to the ability of the material to resist deformation within the elastic deformation range, which is the ratio of stress to strain. The elastic modulus of powder metallurgy materials is usually slightly lower than that of traditional cast or f

Read More

2024-07-23 To address potential electric shocks, leaks, and other safety accidents that may occur during production, as well as to efficiently, timely, and orderly organize rescue and disaster relief efforts after an accident, minimizing casualties and losses, Jiangsu Mimo Metal Co., Ltd. organized an electric

Read More